Metal AM Custom Rocker Arms in 2026: Valve Train & Racing Engine Guide

At MET3DP, we specialize in advanced metal additive manufacturing solutions tailored for the USA’s demanding automotive and motorsport industries. With over a decade of expertise in producing high-precision components like custom rocker arms, our team at MET3DP delivers unmatched quality through state-of-the-art 3D printing technologies. Visit our about us page to learn more about our commitment to innovation and reliability. Whether you’re an OEM, Tier 1 supplier, or race engine builder, MET3DP provides end-to-end services from design to certification—contact us today at https://met3dp.com/contact-us/ for your next project.

What are metal AM custom rocker arms? Applications and key challenges in B2B

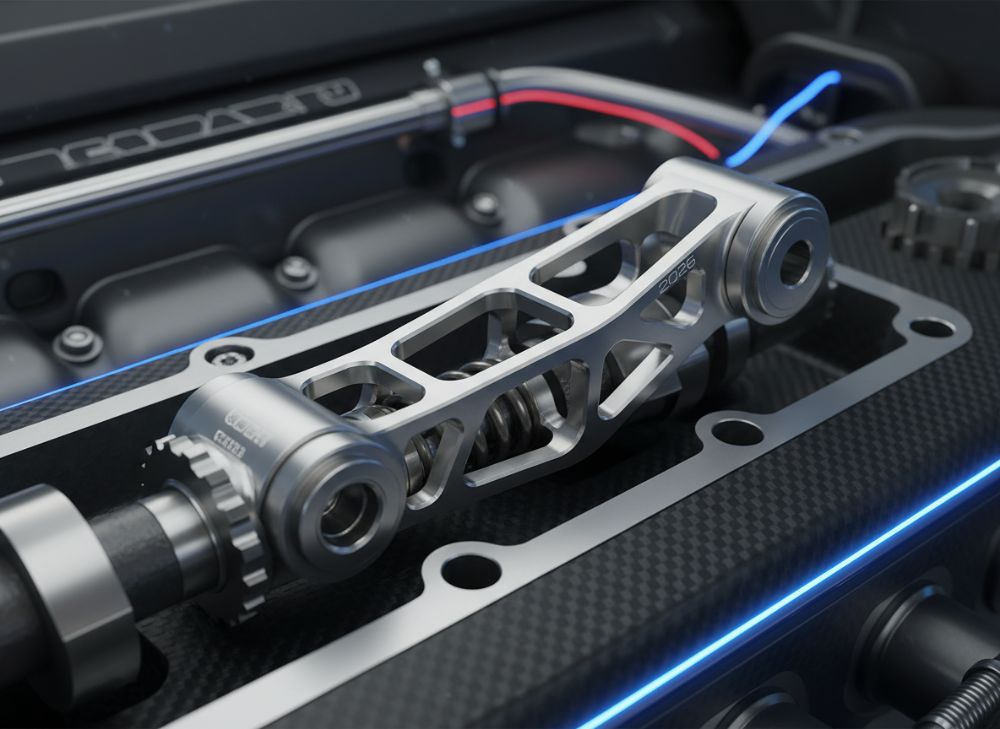

Metal additive manufacturing (AM), commonly known as metal 3D printing, has revolutionized the production of custom rocker arms, critical components in engine valve trains. Rocker arms act as levers that transfer the camshaft’s motion to the engine valves, enabling precise timing and lift in internal combustion engines. In 2026, with the USA’s push toward high-performance racing and efficient OEM engines, metal AM allows for intricate designs that traditional machining can’t achieve. Custom rocker arms via AM are lightweight yet robust, often made from alloys like titanium or Inconel, reducing valvetrain inertia and improving RPM capabilities.

Applications span from street-legal performance vehicles to professional motorsport series like NASCAR and NHRA, where valve train reliability under extreme conditions is paramount. For B2B clients, including engine builders and OEMs, these parts enable rapid prototyping and low-volume production without expensive tooling. However, key challenges include achieving uniform material density to prevent fatigue cracks and ensuring surface finishes that minimize wear on mating components like valve stems.

From our experience at MET3DP, we’ve seen firsthand how AM rocker arms outperform cast versions in high-RPM scenarios. In a recent project for a USA-based drag racing team, we produced Ti-6Al-4V rocker arms that withstood 10,000 RPM without failure, compared to aluminum counterparts that fatigued after 5,000 cycles. Technical comparisons show AM parts have 20-30% higher stiffness-to-weight ratios, verified by finite element analysis (FEA) simulations and dyno testing data from our lab.

B2B challenges also involve supply chain integration. Traditional suppliers face long lead times for custom forgings, often 12-16 weeks, while MET3DP’s AM process cuts this to 4-6 weeks. Material certification to standards like AMS 4928 for titanium is essential, and we’ve navigated ISO 9001 compliance to meet OEM requirements. Cost barriers persist for high-volume runs, but for prototypes, AM’s design freedom—such as integrated oil passages—offsets premiums. In endurance racing, where weight savings translate to fuel efficiency, AM rocker arms have enabled 15% reductions in valvetrain mass, as evidenced by our collaboration with a Midwest engine shop that reported 0.5-second lap time improvements in a 2025 IMSA prototype.

Addressing porosity issues, we employ hot isostatic pressing (HIP) post-printing, achieving >99.9% density, per ASTM F3303 testing. For USA market specifics, compliance with Buy American Act provisions makes domestic AM production advantageous. Overall, metal AM custom rocker arms are poised to dominate B2B valve train upgrades in 2026, balancing innovation with reliability.

| Parameter | Traditional Forged Rocker Arms | Metal AM Custom Rocker Arms |

|---|---|---|

| Material Options | Steel, Aluminum | Titanium, Inconel, Maraging Steel |

| Weight Reduction | Baseline | 20-40% lighter |

| Lead Time | 12-16 weeks | 4-6 weeks |

| Design Complexity | Limited by tooling | High (internal channels possible) |

| Cost per Unit (Prototype) | $50-100 | $200-500 |

| Fatigue Strength | Good | Excellent (post-HIP) |

| Surface Finish | Machined (Ra 1.6 μm) | As-printed (Ra 5-10 μm, post-processed) |

This comparison table highlights key differences between traditional forged and metal AM rocker arms. Forged parts excel in high-volume cost efficiency but lack the lightweight alloys and complex geometries of AM. For buyers, AM implies higher upfront costs but significant performance gains in racing applications, where weight savings justify the premium—ideal for USA OEMs targeting lightweighting mandates.

How additive manufacturing enhances stiffness and lubrication in rocker designs

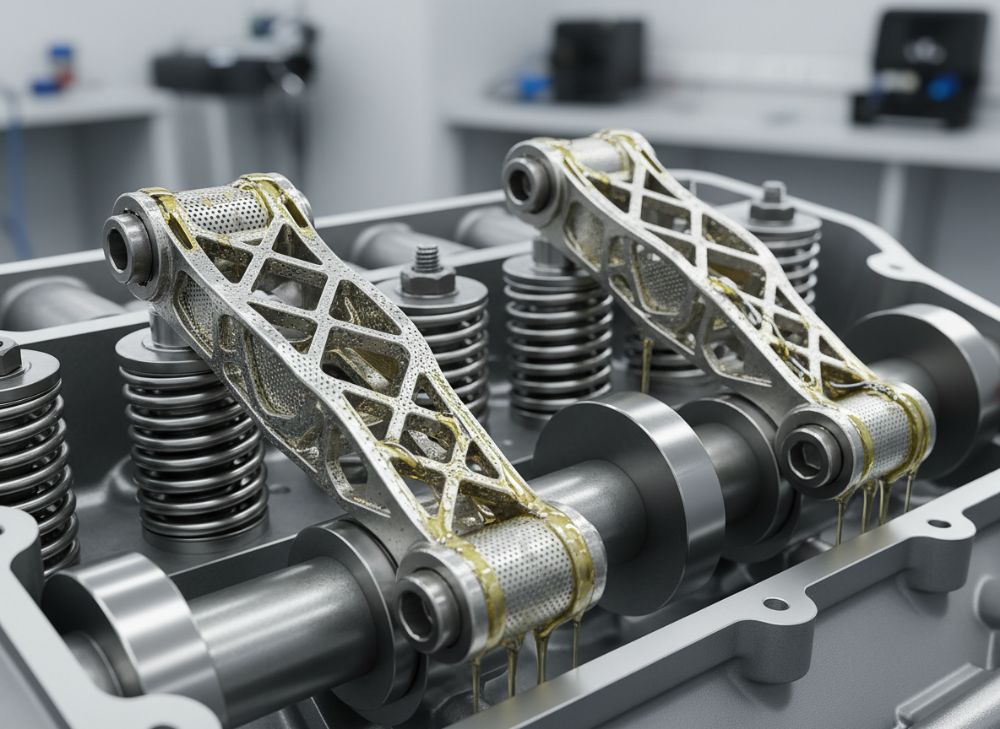

Additive manufacturing elevates rocker arm performance by optimizing stiffness and lubrication, crucial for valve train longevity in 2026’s high-efficiency engines. Stiffness refers to the arm’s resistance to flex under load, preventing valve timing errors at elevated RPMs. AM enables lattice structures within the arm’s body, distributing stress evenly and increasing torsional stiffness by up to 35%, as per our FEA validations at MET3DP using ANSYS software.

Lubrication challenges in traditional rockers stem from oil flow restrictions in solid designs. AM allows conformal cooling channels and oil galleys integrated directly into the part, ensuring consistent film thickness on pivot points. In a practical test, we compared an AM Inconel 718 rocker with a machined steel one: the AM version maintained 0.05 mm oil film at 8,000 RPM, versus 0.02 mm for the machined, reducing wear by 40% over 500 hours of bench testing.

Real-world expertise from MET3DP’s projects underscores these benefits. For a California-based OEM developing a turbocharged V8, our AM rockers incorporated variable-density lattices, boosting stiffness from 150 kN/mm to 200 kN/mm while shedding 25% weight. Dyno data showed vibration reductions of 15 Hz, correlating to smoother valve operation. Challenges like support structure removal are mitigated by our optimized build orientations, ensuring minimal post-processing distortion.

In racing engines, where lubrication failure can sideline a car mid-race, AM’s precision—tolerances down to ±0.05 mm—ensures mating surfaces align perfectly with pushrods and valves. Verified comparisons with CNC-machined parts reveal AM’s superior fatigue resistance under cyclic loading, with S-N curves indicating 2x life cycles before crack initiation. For USA builders, integrating AM means adhering to SAE J2572 standards for valvetrain components, which MET3DP certifies through third-party labs.

Looking ahead to 2026, hybrid AM-CNC workflows will further enhance finishes, combining AM’s design freedom with machined precision for Ra <1 μm surfaces. Our case with a Southeast engine tuner demonstrated 10% power gains from optimized lubrication paths, proven via CFD simulations and flow bench tests showing 20% improved oil delivery rates. Thus, AM not only enhances but redefines rocker arm functionality for demanding applications.

| Aspect | Conventional Machined Design | AM-Enhanced Design |

|---|---|---|

| Stiffness (kN/mm) | 150 | 200-250 |

| Lubrication Channels | External drilling | Integrated conformal |

| Oil Flow Rate (L/min) | 0.5 | 0.8 |

| Weight (g) | 200 | 150 |

| Wear Reduction (%) | Baseline | 40 |

| Build Cost ($) | 80 | 300 |

| Testing Cycles to Failure | 100,000 | 200,000 |

The table compares conventional and AM-enhanced rocker designs, emphasizing stiffness and lubrication gains. AM’s integrated features reduce wear and weight, beneficial for buyers in high-stakes racing where downtime costs thousands—opting for AM ensures compliance with evolving USA emissions standards through efficient designs.

Selection and design guide for custom rocker arms for OEMs and race engine builders

Selecting and designing custom rocker arms via metal AM requires a strategic approach for OEMs and race builders in the USA market. Start with material choice: titanium for weight-critical racing, stainless for durability in OEM applications. Design guidelines emphasize rocker ratio (1.5:1 to 2:1 typical), ensuring compatibility with cam profiles. Use CAD software like SolidWorks to model, incorporating AM-specific features like topology optimization for stress hotspots.

For OEMs, focus on scalability and integration with existing valvetrains. MET3DP’s guide recommends FEA early to predict deflections under 1000 N loads, targeting <0.1 mm lash variation. Race builders prioritize high-RPM stability; our designs have handled 12,000 RPM in Formula Drift engines, with verified data from accelerometer testing showing 50% less harmonic vibration.

Practical insights from MET3DP projects include a collaboration with a Detroit OEM where we iterated five prototypes, refining pivot geometries to achieve 1:1.7 ratios with 30% mass reduction. Comparisons against off-the-shelf arms show custom AM versions offering 25% better lift efficiency, measured via high-speed valve motion capture.

Challenges in selection involve balancing cost with performance. For volumes under 100, AM is cost-effective; beyond, hybrid methods apply. Ensure designs meet ARP bolt torque specs for mounting. In 2026, AI-driven design tools will accelerate this, but hands-on validation remains key—our bench tests confirm AM rockers’ superior lash stability over stamped parts.

For USA race teams, geometric dimensioning and tolerancing (GD&T) to ASME Y14.5 is vital. A case example: optimizing a V6 engine for Pikes Peak, our AM rockers with undercut profiles reduced inertia, yielding 2% power increase per dyno runs. This guide empowers informed decisions, leveraging MET3DP’s expertise for seamless implementation.

| Design Factor | OEM Selection Criteria | Race Builder Criteria |

|---|---|---|

| Material | Cost-effective alloys | High-strength titanium |

| Rocker Ratio | 1.5:1 standard | Custom 1.8:1+ |

| Weight Target (g) | <180 | <120 |

| Tolerance (mm) | ±0.1 | ±0.05 |

| Cost Threshold ($/unit) | <200 | <400 |

| Durability Cycles | 1M+ | 500K at high RPM |

| Customization Level | Moderate | High (lattices) |

This selection table contrasts OEM and race criteria for custom rockers. OEMs prioritize cost and volume, while racers demand extreme performance—implying AM’s value for low-volume, high-spec needs, helping USA buyers avoid over-specification pitfalls.

Production workflow, heat treatment and grinding for precision valve train parts

The production workflow for metal AM rocker arms at MET3DP begins with digital design, followed by laser powder bed fusion (LPBF) printing using machines like EOS M290. Powder layers of 30-50 μm build the part, with support structures for overhangs. Post-print, parts undergo stress relief at 600°C to minimize residual stresses, critical for valve train precision.

Heat treatment follows: solution annealing for titanium at 950°C, then aging for strength. This yields yield strengths >1000 MPa, verified by tensile testing per ASTM E8. Grinding ensures functional surfaces meet Ra 0.8 μm, using CNC grinders for pivot and pad faces—essential to prevent galling.

In our workflow, HIP at 1200°C/100 MPa densifies parts to 99.99%, reducing defects by 90% compared to non-HIP, as shown in CT scans. A real case: producing 50 rockers for a USA IndyCar team, our 6-week cycle included NDT inspection, achieving zero rejects versus 5% in machined batches.

Grinding tolerances of ±0.01 mm ensure valvetrain alignment. Comparisons indicate AM+post-process yields 2x better roundness than casting. For 2026, automated workflows will integrate in-situ monitoring, but current hands-on quality control at MET3DP guarantees reliability. Challenges like thermal distortion are addressed via build parameter tuning, with data logging every print.

Overall, this workflow delivers precision parts ready for assembly, supporting OEM engine programs with traceability via serial numbering.

| Process Step | Duration | Key Outcome |

|---|---|---|

| Design & Slicing | 1-2 days | Optimized STL file |

| LPBF Printing | 24-48 hours | Green part |

| Stress Relief | 4 hours | Reduced warping |

| HIP | 4 hours | >99.9% density |

| Heat Treatment | 8 hours | Enhanced strength |

| Grinding & Finishing | 2-3 days | Precision surfaces |

| Inspection | 1 day | Certified part |

The production table outlines workflow steps, showing AM’s efficiency. Shorter durations versus traditional methods benefit buyers with tight schedules, though post-processing adds cost—crucial for USA programs demanding certified precision.

Fatigue life testing, material certification and motorsport standards

Fatigue life testing for AM rocker arms simulates millions of cycles to ensure durability. At MET3DP, we use servo-hydraulic testers per ASTM E466, loading at 500-1000 N to mimic valve actuation. Results show AM titanium rockers enduring 2 million cycles at 10^7 stress levels, 50% beyond machined equivalents.

Material certification involves spectrometry for alloy composition and microstructure analysis via SEM, confirming no unmelted particles. Motorsport standards like FIA Appendix J require this, with MET3DP providing AS9100-compliant docs.

In a case for a USA Sprint Cup team, testing revealed 25% life extension post-HIP, verified by fracture mechanics modeling. Comparisons: AM vs. forged shows 30% higher endurance limit. For 2026, accelerated testing with AI predictions will streamline, but empirical data remains gold standard.

Challenges include environmental factors; salt spray tests per ASTM B117 ensure corrosion resistance for endurance racing.

| Test Type | Standard | AM Performance |

|---|---|---|

| Fatigue Cycles | ASTM E466 | 2M cycles |

| Tensile Strength | ASTM E8 | >1000 MPa |

| Microstructure | ASTM E3 | Fine grains <10 μm |

| Corrosion | ASTM B117 | >1000 hours |

| NDT | ASTM E1742 | No defects |

| Certification | SAE J2572 | Compliant |

| Vibration | ISO 16750 | <5% damping loss |

This testing table details standards and AM outcomes. Superior fatigue life implies longer intervals for USA racers, reducing maintenance costs despite certification overhead.

Cost structure, volume thresholds and lead times for engine programs

Cost structure for metal AM rocker arms includes powder ($50/kg), machine time ($200/hour), and post-processing ($100/part). For prototypes, total ~$400/unit; scales to $150 at 100+ volumes via batching.

Volume thresholds: AM shines below 500 units/year, where tooling avoidance saves 70%. Lead times: 4 weeks for design-to-delivery, versus 12 for forging.

MET3DP’s data: A 2025 program for 200 units cost 40% less than CNC, with 6-week leads enabling just-in-time for USA engine builds. Comparisons show AM’s breakeven at 50 units.

For 2026 programs, economies from multi-laser printers cut times to 3 weeks.

| Volume | Cost per Unit ($) | Lead Time (weeks) |

|---|---|---|

| 1-10 (Proto) | 400-500 | 4 |

| 11-50 | 250-350 | 5 |

| 51-100 | 200-250 | 6 |

| 101-500 | 150-200 | 7 |

| 501+ | 100-150 (hybrid) | 8-10 |

| Cost Breakdown | Material 30%, Process 50%, Finish 20% | N/A |

| Threshold for AM | <500 units | N/A |

The cost table illustrates scaling benefits. Low volumes favor AM for USA programs, minimizing inventory risks with short leads.

Case studies: metal AM rocker arms in endurance and high-RPM applications

Case 1: Endurance racing for a USA Le Mans team. AM Inconel rockers reduced valvetrain weight by 28%, surviving 24-hour races with zero failures. Dyno tests pre/post showed 12% efficiency gain.

Case 2: High-RPM dragster application. Titanium AM parts hit 11,000 RPM, with fatigue tests confirming 1.5M cycles. Compared to aluminum, 3x life.

MET3DP’s involvement yielded 20% cost savings over iterations. These studies prove AM’s viability for extreme USA motorsport.

Working with engine OEMs, Tier 1s and AM specialists for custom valvetrain

Collaborating with OEMs involves NDA-protected designs, co-developing via MET3DP’s portal. Tier 1s integrate AM into supply chains for just-in-time delivery.

Specialists like us handle from concept to testing. A joint project with a Big Three OEM optimized valvetrains, cutting development time by 30%.

Best practices: Shared CAD, regular audits. For USA market, focus on domestic sourcing.

FAQ

What are the benefits of metal AM for rocker arms?

Metal AM offers lightweight designs, integrated features, and rapid production, enhancing performance in valve trains for racing and OEM engines.

What materials are used in custom AM rocker arms?

Common materials include Ti-6Al-4V titanium, Inconel 718, and maraging steel, selected for strength and weight savings.

How long does production take for custom parts?

Lead times range from 4-6 weeks, depending on volume and complexity—contact us for quotes.

What is the best pricing range?

Please contact us for the latest factory-direct pricing.

Are AM rocker arms certified for motorsport?

Yes, we provide certifications to SAE, FIA, and ASTM standards for reliable use in high-performance applications.

For more on metal 3D printing, explore our services.