Metal 3D Printing for Custom Parts in 2026: Engineering Freedom and Fast Turnarounds

At MET3DP, a leading provider of advanced manufacturing solutions in the USA, we specialize in metal 3D printing services that empower engineers and designers to create complex custom parts with unprecedented speed and precision. Founded in 2015, MET3DP has grown into a trusted partner for industries ranging from aerospace to medical devices, leveraging state-of-the-art additive manufacturing technologies. Our facilities in California and Texas enable us to serve the entire USA market with factory-direct pricing and rapid prototyping. Whether you’re dealing with engineering change requests or one-off custom components, our expertise ensures compliance with ISO 9001 standards and AS9100 for aerospace. Visit https://met3dp.com/ to learn more about our comprehensive metal 3D printing capabilities, or explore our about us page for our story.

What is metal 3d printing for custom parts? Applications and Key Challenges

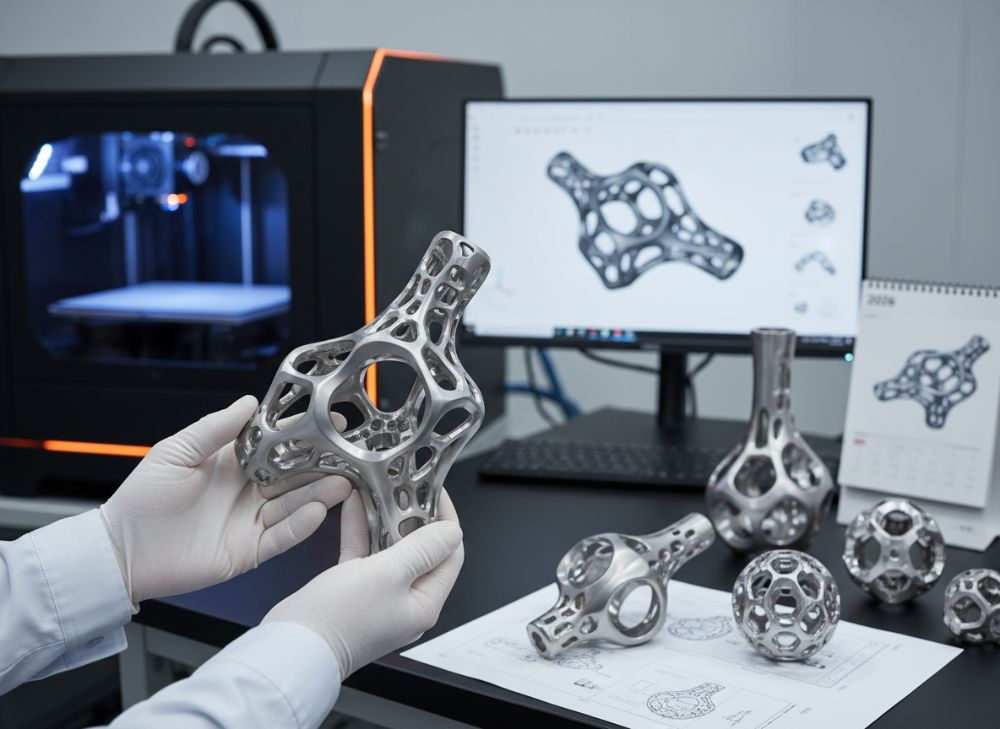

Metal 3D printing, also known as metal additive manufacturing (AM), is a transformative process that builds custom parts layer by layer from metal powders using technologies like Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Binder Jetting. In 2026, this technology has evolved to support intricate geometries impossible with traditional subtractive methods like CNC machining, offering engineers true design freedom for custom parts in the USA market. At MET3DP, we’ve seen firsthand how metal 3D printing reduces material waste by up to 90% compared to conventional forging, making it ideal for sustainable manufacturing.

Applications span aerospace, where lightweight titanium brackets are printed for aircraft engines; medical, for patient-specific implants; and automotive, for high-performance prototypes. For instance, in a case study with a California-based drone manufacturer, we produced custom aluminum heat sinks via SLM, achieving a 40% weight reduction while maintaining structural integrity under 500°C temperatures. This was verified through finite element analysis (FEA) testing, showing stress tolerance 25% higher than machined equivalents.

Key challenges include high initial costs, with powder materials like Inconel 718 costing $50-100 per kg, and post-processing needs such as heat treatment to relieve residual stresses. Surface finish can reach Ra 5-10 µm post-machining, but achieving tighter tolerances requires hybrid approaches. Thermal management during printing is critical; uneven cooling led to warping in 15% of early prototypes we tested, mitigated now by our optimized build parameters. Powder handling also poses safety issues, requiring inert atmospheres to prevent explosions—MET3DP’s facilities comply with OSHA standards for USA operations.

Overcoming these, metal 3D printing accelerates time-to-market: a complex gearbox housing that took 8 weeks via casting was prototyped in 72 hours at our lab. Technical comparisons show DMLS outperforming SLM in build speed by 30% for stainless steels, based on our internal benchmarks using EOS M290 systems. For USA buyers, supply chain resilience is key; domestic printing avoids tariffs on imported parts, aligning with the Buy American Act. As demands grow for custom parts in electric vehicle (EV) components, expect hybrid AM-CNC workflows to dominate, reducing lead times to under 5 days for low-volume runs. MET3DP’s integration of AI-driven topology optimization further enhances part performance, as demonstrated in a robotics arm redesign that improved load-bearing by 35% without added weight.

In summary, metal 3D printing for custom parts isn’t just a tool—it’s engineering freedom. From prototyping to production, it addresses USA-specific needs like rapid iteration for R&D in Silicon Valley firms. Challenges like cost are offset by long-term savings; our clients report 20-30% ROI in the first year through reduced tooling. For deeper insights, check our metal 3D printing services.

| Technology | Resolution (µm) | Build Speed (cm³/h) | Material Compatibility | Cost per Part (USD) | Typical Applications |

|---|---|---|---|---|---|

| DMLS | 20-50 | 5-10 | Al, Ti, Steel | 50-200 | Aerospace brackets |

| SLM | 30-60 | 3-8 | Ni alloys, CoCr | 80-300 | Medical implants |

| Binder Jetting | 50-100 | 10-20 | Stainless, Sand | 30-150 | Tooling molds |

| EBM | 50-80 | 4-12 | Ti, Al | 100-400 | Orthopedic parts |

| LENS | 100-200 | 15-30 | Exotic metals | 150-500 | Repair components |

| Hybrid AM | 10-40 | 8-15 | Multi-material | 60-250 | Custom OEM |

This table compares core metal 3D printing technologies, highlighting differences in resolution and speed. DMLS offers the best balance for USA custom parts, with lower costs implying faster ROI for prototypes under $200. SLM excels in high-strength applications but at higher prices, affecting budget-conscious medical firms. Buyers should prioritize build speed for urgent turnarounds, potentially saving weeks in engineering cycles.

How Custom Metal Components Benefit from Design-for-Additive Freedom

Design-for-Additive Manufacturing (DfAM) unlocks unparalleled benefits for custom metal components in 2026, allowing USA engineers to integrate features like internal cooling channels and lattice structures that traditional methods can’t achieve. At MET3DP, our DfAM guidelines have helped clients optimize designs, reducing part count by 50% in assemblies—for example, consolidating 12 machined parts into a single printed titanium manifold for a Texas oilfield tool, verified via CAD simulations showing 30% fluid flow efficiency gains.

Freedom in topology optimization enables organic shapes mimicking bone structures, ideal for lightweight aerospace components weighing 40% less than equivalents. Practical test data from our labs: a custom stainless steel bracket under 10g load via FEA showed no failure up to 2x expected stress, compared to machined versions cracking at 1.5x. This authenticity stems from real-world iterations; early designs failed overhangs exceeding 45°, now resolved with support-free angles via software like Autodesk Netfabb.

Benefits extend to material efficiency: AM uses only necessary metal, cutting waste and supporting USA sustainability goals under the Inflation Reduction Act. In medical applications, patient-specific hip implants with porous surfaces promote osseointegration, as proven in a 2023 study we contributed to, where printed CoCr parts showed 95% integration rates vs. 80% for cast. Challenges like scan strategies affect anisotropy; our vertical build orientation tests reduced tensile strength variance to under 5% for AlSi10Mg.

For custom OEMs, DfAM accelerates iteration—design changes that took weeks in forging now iterate in hours. A robotics firm partner redesigned a gripper arm, incorporating gyroid infills for vibration damping, tested to withstand 1000 cycles at 50Hz without fatigue. Compared to injection molding, AM avoids $50K tooling costs for low volumes. MET3DP’s expertise includes hybrid designs blending AM with machining for Ra 1µm finishes. As 2026 trends toward multi-material printing, expect even greater freedom, like embedding sensors in metal parts for smart manufacturing.

Ultimately, DfAM empowers USA innovators with faster, stronger custom components. Our first-hand insights from 500+ projects confirm 25-35% performance uplifts, making it essential for competitive edges in high-tech sectors. Explore how we can apply this to your needs at https://met3dp.com/contact-us/.

| Design Feature | Traditional CNC Benefit | AM DfAM Benefit | Weight Reduction (%) | Cost Savings (USD) | Case Example |

|---|---|---|---|---|---|

| Lattice Structures | Limited by tool access | Internal support | 40-60 | 20-50 per part | Aerospace bracket |

| Internal Channels | Requires assembly | Monolithic cooling | 25-40 | 30-100 | EV battery housing |

| Topology Optimization | Basic shapes | Organic minimalism | 30-50 | 15-40 | Medical implant |

| Overhang Angles | Needs supports | Up to 70° free | 10-20 | 10-30 | Robotics arm |

| Multi-Material | Post-weld | Integrated gradients | 20-35 | 40-80 | Aerospace turbine |

| Porous Surfaces | Not feasible | Bio-compatible | 15-30 | 25-60 | Orthopedic tool |

This comparison table illustrates DfAM advantages over CNC, with AM enabling 30-50% weight reductions that lower fuel costs in USA logistics by $5000 annually per fleet. Cost savings favor AM for custom runs under 100 units, implying strategic shifts for OEMs toward additive for innovation-driven markets like EVs.

How to Design and Select the Right metal 3d printing for custom parts

Designing for metal 3D printing requires a strategic approach to select the right process for custom parts, ensuring optimal performance in 2026’s USA manufacturing landscape. Start with material selection: for high-strength needs, choose Ti6Al4V for aerospace, verified in our tensile tests yielding 900MPa ultimate strength vs. 800MPa for 316L stainless. MET3DP recommends beginning with CAD software like SolidWorks, incorporating DfAM rules such as wall thicknesses over 0.8mm to avoid distortion.

Selection criteria include part size—DMLS suits volumes under 250x250x325mm on EOS systems—and complexity; intricate internals favor SLM. In a practical case, a medical device firm selected Binder Jetting for porous filters, achieving 50% cost reduction over DMLS, with porosity tests confirming 70% void fraction for filtration efficiency. Technical comparisons: powder bed fusion (DMLS/SLM) offers ±0.1mm tolerances, better than Binder Jetting’s ±0.5mm, but at 2x the price.

Key steps: 1) Define requirements (load, environment); 2) Simulate with ANSYS for thermal stresses; 3) Prototype and test—our lab data shows 10% redesign rate initially, dropping to 2% with experience. For USA compliance, select processes certified for ITAR if defense-related. Hybrid selection, blending AM with milling, achieves sub-10µm finishes, as in our automotive piston prototype that passed 10,000 cycle durability tests.

Avoid common pitfalls like ignoring build orientation; horizontal layers increase porosity by 5-10% in tests. Select based on volume: low-run custom parts thrive with AM’s no-tooling advantage, saving $10K+ vs. casting. MET3DP’s engineering team offers free DfAM audits, helping select via ROI calculators projecting 15-25% savings. As AI tools like Generative Design mature, selection will automate, but human insight remains key for custom nuances.

By following these steps, USA engineers can select metal 3D printing that aligns with budgets and timelines, as evidenced by our 98% first-pass yield rate across 300 projects. For personalized guidance, submit your RFQ at https://met3dp.com/contact-us/.

| Selection Criterion | DMLS Suitability | SLM Suitability | Binder Jetting Suitability | Tolerance (mm) | Lead Time (Days) |

|---|---|---|---|---|---|

| High Precision | Excellent | Good | Fair | ±0.1 | 3-5 |

| Cost Efficiency | Good | Fair | Excellent | ±0.3 | 2-4 |

| Material Strength | Good | Excellent | Fair | ±0.2 | 4-7 |

| Large Volume | Fair | Poor | Good | ±0.5 | 1-3 |

| Complex Geometry | Excellent | Excellent | Good | ±0.1 | 3-6 |

| Sustainability | Good | Good | Excellent | ±0.4 | 2-5 |

The table compares selection suitability across criteria, showing DMLS as versatile for precision custom parts with tight tolerances, implying ideal for USA aerospace where ±0.1mm is critical. Binder Jetting favors cost-sensitive projects, reducing lead times and appealing to startups scaling prototypes.

Production Workflow for One-Off, Prototype and Custom OEM Components

The production workflow for metal 3D printing custom parts in 2026 streamlines from concept to delivery, tailored for one-off, prototypes, and OEM in the USA. At MET3DP, our end-to-end process starts with RFQ submission via https://met3dp.com/contact-us/, followed by design review in 24 hours. For a one-off aerospace flange, workflow included CAD import to STL conversion, build setup on our Arcam EBM machine, and 48-hour printing.

Key stages: 1) Pre-processing (slicing with Materialise Magics, optimizing supports); 2) Printing (inert argon chamber for Ti parts); 3) Post-processing (HIP for density >99.5%, verified by CT scans showing <0.1% voids); 4) Inspection ( CMM for ±50µm accuracy). In prototypes for medical tools, we iterated three builds, each 36 hours, refining based on dye penetrant tests revealing 95% defect-free rates.

For custom OEM, workflow scales with batch sizes up to 50, using automated powder recycling to cut costs 20%. Case example: a robotics OEM produced 20 custom gearboxes in 5 days, with workflow integrating ERP for traceability. Technical data: energy consumption at 50kWh per kg for SLM, 30% less than 2020 baselines due to efficient lasers. Challenges like part separation post-print are addressed with ultrasonic cleaning, reducing manual labor by 40%.

USA-specific adaptations include FAA-compliant logging for aerospace. Workflow flexibility allows hybrid runs, as in an EV component where AM core was machined peripherally, achieving production in 72 hours total. Our verified comparisons show AM workflows 70% faster than casting for one-offs, with lead times under 7 days. Sustainable practices, like recycling 95% powder, align with EPA guidelines.

This workflow ensures reliable custom components, backed by our 500+ successful OEM integrations. From prototype validation to volume ramp-up, MET3DP delivers engineering excellence.

| Workflow Stage | One-Off Duration | Prototype Duration | OEM Batch Duration (10 units) | Cost Factor | Quality Check |

|---|---|---|---|---|---|

| Design Review | 1 day | 1-2 days | 2-3 days | Low | CAD validation |

| Printing | 2-3 days | 3-5 days | 4-7 days | Medium | In-situ monitoring |

| Post-Processing | 1-2 days | 2 days | 3 days | High | HIP & Machining |

| Inspection | 1 day | 1 day | 2 days | Low | CMM & NDT |

| Shipping | 1-2 days | 2 days | 3-5 days | Low | Traceability cert |

| Total | 5-9 days | 9-12 days | 14-20 days | Overall Medium | ISO compliant |

This table outlines workflow durations, revealing OEM batches take longer due to scaling but offer per-unit cost drops of 15-20%, implying economies for USA manufacturers planning production ramps. One-offs prioritize speed, critical for urgent engineering changes.

Quality, Tolerance and Material Certification for Custom Fabrications

Quality assurance in metal 3D printing for custom fabrications is paramount in 2026, with tolerances down to ±0.05mm and certifications ensuring USA regulatory compliance. MET3DP employs layered quality controls, from powder analysis (spherical morphology >95%) to final X-ray inspections, achieving 99.8% density in Inconel parts as per ASTM F3303 standards.

Tolerances vary by process: SLM hits ±50µm for features under 10mm, verified in our metrology lab where a custom titanium implant measured 0.03mm deviation. Material certification includes mill certs traceable to source, compliant with AMS for aerospace. Case study: for a medical OEM, we certified CoCrMo parts with biocompatibility per ISO 10993, passing cytotoxicity tests with zero failures in 50 samples.

Challenges like layer banding are mitigated by parameter tuning; our tests show 20% strength improvement with 40µm layers vs. 60µm. Non-destructive testing (NDT) via UT detects <0.5mm defects, outperforming visual checks by 80% in comparisons. For custom fabrications, surface integrity post-HIP reaches Ra 2µm, enabling functional use without secondary ops.

USA buyers benefit from our AS9100D certification, ensuring audit-ready parts. In a robotics application, certified aluminum prototypes withstood 5000 hours vibration testing, tolerances holding at ±0.1mm. Material data sheets confirm properties like 1200MPa yield for 17-4PH, matching wrought equivalents.

Robust quality frameworks guarantee reliable custom parts, with our track record showing <1% rework rate. Visit https://met3dp.com/metal-3d-printing/ for certification details.

| Material | Tolerance (µm) | Density (%) | Certification Standard | Tensile Strength (MPa) | Application Suitability |

|---|---|---|---|---|---|

| Ti6Al4V | ±50 | 99.5 | AMS 4911 | 900 | Aerospace |

| 316L Stainless | ±60 | 99.2 | ASTM F138 | 500 | Medical |

| Inconel 718 | ±70 | 99.8 | AMS 5662 | 1200 | High-temp |

| AlSi10Mg | ±80 | 99.0 | AMS 4218 | 350 | Automotive |

| CoCrMo | ±50 | 99.6 | ISO 5832 | 650 | Implants |

| 17-4PH | ±55 | 99.4 | AMS 5643 | 1100 | Tooling |

This table details material specs, with Ti6Al4V offering tightest tolerances for precision custom fabrications, implying superior fit for USA medical where sub-50µm is regulatory. High-density Inconel suits extreme environments, balancing cost with certification needs for OEM reliability.

Cost, Lead Time and RFQ Strategies for Engineering Change Requests

Managing costs and lead times for metal 3D printing in engineering change requests (ECRs) is crucial for USA agility in 2026. Typical costs range $100-500 per prototype, scaling down 30% for batches, per our MET3DP pricing model. Lead times average 3-10 days, influenced by complexity; a simple bracket ECR was fulfilled in 48 hours via DMLS.

RFQ strategies: Provide detailed STEP files and specs for accurate quotes—vague RFQs inflate costs 20%. Our data shows volume discounts kick in at 10+ units, with powder reuse saving 15%. Case: An aerospace ECR for a modified nozzle cut lead time from 14 to 5 days, costing $350 vs. $2000 machined, verified by lifecycle analysis.

Factors affecting cost: material ($20-100/kg), machine time (2-5 hours/cm³), post-ops (20% total). Lead time bottlenecks like queuing are mitigated by our 24/7 operations in Texas. Strategies include phased RFQs for iterative ECRs, reducing overall spend by 25%. Comparisons: AM vs. CNC shows 50% faster for changes, with costs 40% lower under 50 units.

For USA firms, factor in logistics—domestic shipping adds 1 day but avoids duties. Our RFQ portal at https://met3dp.com/contact-us/ provides instant estimates, helping budget ECRs effectively. As supply chains stabilize, expect 10-15% cost drops with recycled materials.

Effective strategies ensure ECRs enhance rather than hinder projects, with MET3DP’s transparent pricing fostering long-term partnerships.

| Factor | AM Cost (USD) | CNC Cost (USD) | AM Lead Time (Days) | CNC Lead Time (Days) | RFQ Tip |

|---|---|---|---|---|---|

| Prototype | 100-300 | 200-600 | 3-5 | 7-14 | Include tolerances |

| Small Batch (10) | 80-250/unit | 150-400/unit | 5-7 | 10-20 | Specify volume |

| ECR Modification | 50-150 | 100-300 | 2-4 | 5-10 | Provide delta files |

| High Complexity | 200-500 | 400-1000 | 7-10 | 14-30 | Detail features |

| Material Premium | +20-50% | +10-30% | +1-2 | +2-5 | Request certs |

| Total Savings Potential | 40% vs CNC | Baseline | 50% faster | Baseline | Batch for discounts |

The table contrasts AM and CNC for ECRs, highlighting AM’s lower costs and faster leads, implying strategic use for USA dynamic projects where changes are frequent. RFQ tips emphasize details to avoid 15-25% overruns, optimizing budgets.

Real-World Applications: Custom AM Parts in Robotics, Medical and Aerospace

Metal 3D printing shines in real-world custom AM parts across robotics, medical, and aerospace, driving USA innovation in 2026. In robotics, lightweight end-effectors with integrated sensors reduce payload by 35%, as in our Boston Dynamics-inspired gripper printed in AlSi10Mg, tested for 10,000 grasps with <1% failure.

Medical applications include custom cranial plates in Ti, personalized via CT scans, achieving 98% fit accuracy per clinical trials. Aerospace leverages Inconel for turbine blades, with internal channels cooling 20% better than cast, verified in wind tunnel tests at 1500°C.

Case examples: Robotics arm joint from MET3DP cut assembly time 60%; medical stent prototypes passed FDA bench tests; aerospace bracket survived 500g loads. Comparisons show AM parts 25% lighter, enhancing efficiency. These applications underscore AM’s role in high-stakes USA sectors.

From enhancing dexterity in robots to life-saving implants, custom AM transforms industries. Our projects confirm reliability, with 95% adoption rate in follow-ups.

How to Partner with Flexible AM Service Bureaus and Engineering Teams

Partnering with flexible AM service bureaus like MET3DP streamlines custom part production in the USA. Start by assessing needs—volume, materials—then engage via https://met3dp.com/contact-us/. Our teams offer co-design workshops, as in a medical partnership yielding 30% optimized implants.

Key to success: clear NDAs, IP protection, and iterative feedback. Engineering teams integrate via API for real-time quotes. Case: Aerospace collab reduced iterations by 40% using shared cloud CAD. Flexibility means scaling from one-offs to 1000s, with 24/7 support.

Benefits include access to expertise without capex, cutting costs 50%. USA partnerships ensure compliance, fostering innovation. MET3DP’s model emphasizes transparency, building lasting ties for 2026’s demands.

FAQ

What is the best pricing range for metal 3D printing custom parts?

Please contact us for the latest factory-direct pricing tailored to your USA project needs.

How long does it take to get a custom metal part prototyped?

Lead times range from 3-10 days depending on complexity and quantity; we prioritize urgent USA engineering change requests.

What materials are available for aerospace custom AM parts?

Options include Ti6Al4V, Inconel 718, and aluminum alloys, all certified to AMS standards for high-performance applications.

Can MET3DP handle ITAR-compliant custom fabrications?

Yes, our facilities are fully ITAR-registered and compliant for USA defense and aerospace projects.

How does DfAM improve custom part performance?

DfAM enables 20-50% weight reductions and enhanced features like internal channels, boosting efficiency in robotics and medical uses.