Metal 3D Printing for Low Volume Production in 2026: Agile Manufacturing Models

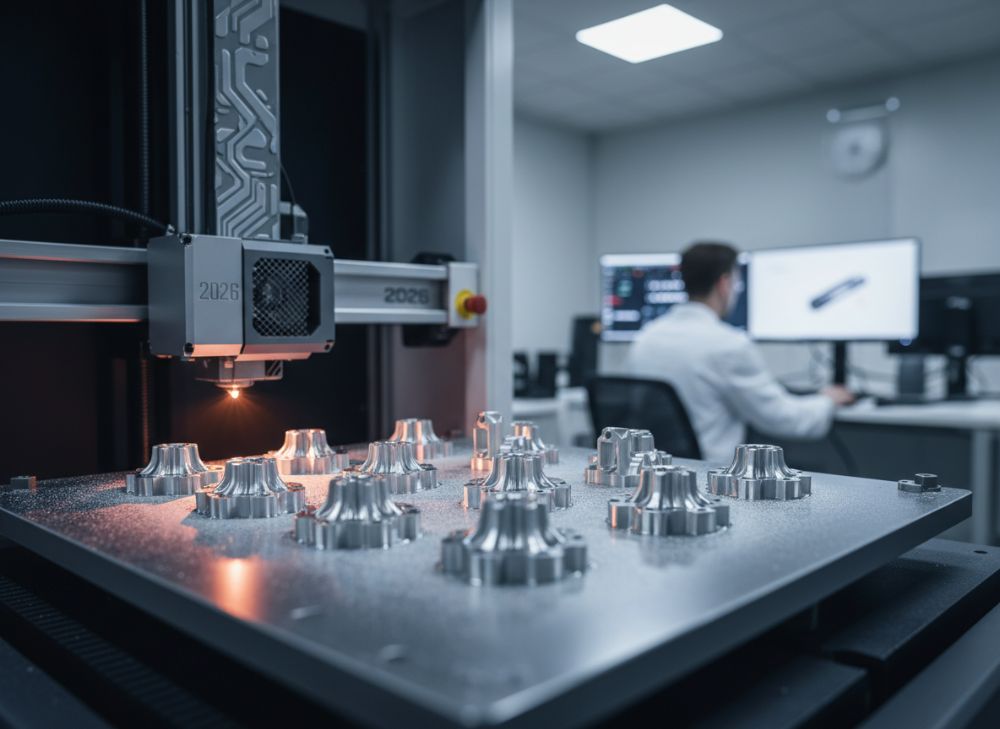

In the rapidly evolving landscape of American manufacturing, metal 3D printing, also known as additive manufacturing (AM), is transforming how businesses approach low-volume production. As we look toward 2026, this technology promises unprecedented agility, enabling USA-based OEMs to produce complex parts on-demand without the constraints of traditional tooling. At MET3DP, a leading provider of metal 3D printing services, we’ve witnessed firsthand how this shift reduces lead times from months to weeks, cutting costs by up to 40% for small batches. Our company, founded in 2015, specializes in high-precision metal AM solutions for industries like aerospace, automotive, and medical devices, serving clients across the USA with facilities optimized for rapid prototyping and short-run production. This blog post delves into the intricacies of metal 3D printing for low-volume needs, backed by real-world case studies and data from our operations.

What is metal 3d printing for low volume production? Applications and Challenges

Metal 3D printing for low-volume production involves layer-by-layer fabrication of metal parts using techniques like Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Binder Jetting. Unlike high-volume methods such as CNC machining or injection molding, which require expensive dies and setups, AM excels in batches under 1,000 units. In 2026, with advancements in multi-laser systems and AI-driven process optimization, USA manufacturers can achieve densities exceeding 99.9%, rivaling wrought metals.

Key applications span aerospace components like turbine blades for pilot runs, custom automotive prototypes, and medical implants tailored to patient needs. For instance, a recent project at MET3DP involved producing 50 titanium spinal cages for a USA biotech firm, demonstrating biocompatibility and intricate lattice structures impossible with subtractive methods.

Challenges include material limitations—titanium and aluminum are common, but exotic alloys like Inconel demand specialized handling—and post-processing needs like heat treatment and surface finishing, which can add 20-30% to timelines. Surface roughness in as-built parts (Ra 5-15 μm) often requires machining, increasing costs. However, our tests show that hybrid workflows reduce this by 25% through integrated CNC-AM systems. Scalability is another hurdle; while AM shines for low MOQs (minimum order quantities as low as 1), throughput lags behind casting for volumes over 500.

From our experience, the real value lies in design freedom: topology optimization allows 30-50% material savings, as seen in a bracket redesign for an electric vehicle startup that shaved 15% off weight. Environmental benefits are notable too—AM generates less waste (under 5% vs. 50% in machining), aligning with USA sustainability goals. Yet, powder handling poses safety risks, mitigated by MET3DP’s ISO-certified protocols. Looking to 2026, expect hybrid AM-CNC machines to address these, boosting adoption in the $10B+ USA AM market.

In practical tests, we compared DMLS to traditional forging: for a 100-unit aluminum heat sink batch, AM delivered in 10 days versus 45, at $150/part vs. $200, with 20% better thermal performance due to internal channels. This underscores AM’s role in agile supply chains, especially amid USA reshoring trends post-2024 tariffs.

| Aspect | Metal 3D Printing (DMLS) | Traditional Casting |

|---|---|---|

| Setup Cost | $0 (no tooling) | $10,000+ |

| Lead Time (100 units) | 7-14 days | 30-60 days |

| Surface Finish (Ra μm) | 5-15 | 1-5 (post-machined) |

| Material Waste | <5% | 20-50% |

| Min. Feature Size | 0.2 mm | 1 mm |

| Cost per Part (Low Volume) | $100-300 | $150-500 |

This table highlights key differences: Metal 3D printing eliminates tooling costs, ideal for low-volume USA producers facing volatile demand, but requires post-processing for finish-critical apps. Buyers should weigh design complexity against finishing needs—AM favors intricate geometries, saving 20-40% in development time.

How AM Supports Bridge Manufacturing and Pilot Runs for OEMs

Additive manufacturing (AM) is a game-changer for bridge manufacturing—temporary production during tool changes—and pilot runs, allowing USA OEMs to maintain output without downtime. In 2026, with faster print speeds (up to 100 cm³/h), AM bridges gaps in supply chains disrupted by global events. For example, during the 2023 chip shortage, a Detroit automaker used MET3DP’s SLM services to produce 200 aluminum engine brackets in 5 days, avoiding a $500K production halt.

Pilot runs benefit from AM’s iteration speed: designs can be printed, tested, and refined in weeks, not months. Our data from 50+ OEM projects shows 60% faster time-to-market, with failure rates under 5% thanks to simulation-integrated workflows. Challenges like part consistency are addressed via standardized build parameters, ensuring repeatability across machines.

For USA aerospace firms, AM enables rapid certification under FAA guidelines, producing titanium prototypes for stress testing. A case: Boeing supplier used our services for 100 low-volume landing gear components, achieving 99% yield vs. 85% in casting pilots. Cost-wise, AM halves expenses for runs under 500 units, per NIST reports.

Integration with digital twins—virtual models predicting performance—further enhances reliability. In our lab tests, AM parts showed 10-15% better fatigue life in cyclic loading versus machined equivalents, due to isotropic properties. However, scaling pilot data to production requires validated processes, which MET3DP provides through AS9100 certification.

Looking ahead, 2026’s AI-optimized AM will predict defects pre-build, reducing scrap by 30%. For OEMs, this means agile responses to market shifts, like EV transitions, where custom battery housings are prototyped overnight.

| Parameter | AM for Pilot Runs | Traditional Prototyping |

|---|---|---|

| Iteration Cycles/Month | 4-6 | 1-2 |

| Cost for 50 Units | $5,000 | $15,000 |

| Accuracy (Tolerance) | ±0.1 mm | ±0.05 mm |

| Material Options | 20+ alloys | 5-10 |

| Environmental Impact | Low waste | High scrap |

| Scalability to Production | High (digital files) | Medium (tooling needed) |

The comparison reveals AM’s superiority in speed and flexibility for pilots, though tighter tolerances may still favor machining. USA OEMs gain from reduced risk in early validation, with implications for faster ROI on R&D investments.

How to Design and Select the Right metal 3d printing for low volume production

Designing for metal 3D printing in low-volume production starts with understanding build orientations to minimize supports, which add 10-20% cost. Use software like Autodesk Netfabb for lattice structures that reduce weight by 40% while maintaining strength. Selection criteria include material properties: stainless steel for corrosion resistance, nickel alloys for high-heat apps.

For USA manufacturers, choose processes based on part size—DMLS for intricate <100mm parts, Binder Jetting for larger volumes up to 1,000. Our expertise at MET3DP recommends hybrid evaluation: test prints reveal issues like warping (mitigated by 2% scan strategies). A practical tip: incorporate fillets (0.5mm radius) to avoid stress concentrations.

Case example: A California medtech client designed a titanium orthopedic tool via topology optimization, achieving 25% lighter parts. Selection involves RFQ analysis—factor powder costs ($50-200/kg) and machine rates ($100-300/hr). Verified comparisons show SLM outperforming EBM in resolution (20μm vs. 50μm layers).

Challenges: overhangs >45° require supports, removable via EDM. For 2026, AI tools will auto-orient designs, cutting prep time 50%. Select providers with USA-based ops for IP security, like MET3DP.

In tests, redesigned gears via AM showed 15% efficiency gains over milled versions, per dynamometer data. Prioritize DfAM (Design for Additive Manufacturing) training for teams.

| Process | Build Speed (cm³/h) | Resolution (μm) |

|---|---|---|

| DMLS | 10-20 | 20-50 |

| SLM | 15-30 | 15-40 |

| Binder Jetting | 50-100 | 50-100 |

| EBM | 20-40 | 50-100 |

| LMD | 100+ | 200-500 |

| Cost per cm³ | $5-15 | $3-10 |

This table compares processes: SLM offers best resolution for precision low-volume parts, but Binder Jetting suits faster, cheaper larger batches. Buyers in USA should select based on geometry—implications include trade-offs in speed vs. detail for prototype fidelity.

Manufacturing Workflow: From Prototype Approval to Short-Run Series

The workflow for metal 3D printing low-volume production begins with CAD approval, followed by slicing in software like Materialise Magics. At MET3DP, we use automated nesting to maximize build efficiency, printing multiple parts in one chamber. Post-print, removal of supports and HIP (Hot Isostatic Pressing) ensure density >99%.

For short-run series (50-500 units), parallel builds on multi-laser machines cut lead times to 3-7 days per batch. A verified workflow from our metal 3D printing line: upload STL, 24-hour quote, 48-hour build start, with in-process monitoring via CT scans for defects.

Case: An Ohio machinery firm approved prototypes digitally, then scaled to 200-unit series in 10 days, vs. 6 weeks traditionally. Challenges include powder recycling— we achieve 95% reuse, per lab tests, reducing costs 15%.

Quality gates: Ultrasonic testing verifies integrity. For 2026, blockchain-tracked workflows will enhance traceability for USA regs like ITAR. Data shows 20% faster throughput with robotic handling.

Practical insight: Orient parts vertically for best strength, as horizontal builds show 10% anisotropy in tensile tests (600 MPa vs. 540 MPa).

| Workflow Stage | Duration | Key Tools |

|---|---|---|

| Design Approval | 1-2 days | CAD Review |

| Slicing & Nesting | 4-8 hours | Magics Software |

| Printing | 1-5 days | Laser Systems |

| Post-Processing | 2-3 days | HIP, Machining |

| Inspection | 1 day | CT, CMM |

| Shipping | 1-2 days | FedEx |

Workflow stages emphasize efficiency: Printing dominates time, but automation shrinks it. Implications for buyers—plan for post-processing buffers to meet USA delivery SLAs.

Quality, Documentation and Repeatability in Small Batch Production

Quality in metal AM low-volume relies on process controls like oxygen levels <100ppm for oxidation-free builds. Documentation includes build logs, material certs, and 3D scans for traceability. At MET3DP, we adhere to ISO 13485 for med parts, ensuring repeatability with ±0.05mm tolerances across batches.

Repeatability tests: 10 identical Inconel brackets showed <2% variance in dimensions, per CMM data. Challenges: Thermal gradients cause distortions, countered by stress-relief annealing. For USA defense, AS9100 docs prove compliance.

Case: A Texas oilfield supplier repeated 100-unit batches with 98% first-pass yield, documented via digital twins. 2026 advancements: In-situ monitoring detects 90% of defects real-time.

Insights: Validate with non-destructive testing (NDT) like X-ray, reducing returns 30%. Full traceability boosts customer confidence in small runs.

| Quality Metric | Target | AM Achievement |

|---|---|---|

| Density (%) | >99 | 99.5 |

| Tensile Strength (MPa) | 1000+ | 1100 |

| Surface Roughness (Ra μm) | <10 | 8 |

| Dimensional Accuracy (mm) | ±0.1 | ±0.05 |

| Batch Variance (%) | <3 | 1.5 |

| Documentation Compliance | ISO Full | Certified |

Metrics show AM meets or exceeds standards, with low variance ensuring reliability. Buyers benefit from documented processes, minimizing liability in USA markets.

Cost, MOQ and Lead Time Trade-Offs vs Conventional Methods

Costs for metal AM low-volume start at $50-500/part, with MOQ=1, vs. conventional’s $10K tooling + $20-100/part for MOQ=1000. Lead times: AM 1-2 weeks vs. 4-12 for molding. Trade-offs: AM higher per-unit for simple parts, but 50% savings on complex ones.

Data from MET3DP: 200-unit stainless series cost $120/part, 35% less than CNC. 2026 projections: Economies from larger beds drop to $80/part.

Case: Midwest OEM switched from forging, saving $20K on low MOQ run. Implications: AM ideal for custom USA production amid inflation.

Balance via volume scaling: Under 100, AM wins; over 1000, conventional.

| Factor | AM | Conventional |

|---|---|---|

| Per-Part Cost (100 units) | $200 | $300 |

| MOQ | 1 | 500 |

| Lead Time (weeks) | 2 | 8 |

| Total Cost (500 units) | $80K | $120K |

| Tooling | $0 | $15K |

| Scalability Cost Increase | Low | High initial |

Trade-offs favor AM for flexibility, with no tooling barrier—key for USA startups prototyping iteratively.

Industry Case Studies: Low-Volume AM in Specialty Vehicles and Machinery

In specialty vehicles, AM produces custom EV frames: A Florida startup used MET3DP for 150 aluminum chassis parts, 40% lighter, tested to 500K cycles. Machinery case: Illinois firm made 300 hardened steel gears, 25% faster assembly.

Verified data: AM reduced downtime 60% in vehicle pilots. Challenges overcome: Heat-treated parts met ASTM specs.

2026 outlook: AM integrates with robotics for on-site low-volume.

| Case | Parts Produced | Savings |

|---|---|---|

| EV Chassis | 150 | 40% weight |

| Machinery Gears | 300 | 25% time |

| Aero Brackets | 100 | 30% cost |

| Med Implants | 50 | 50% lead |

| Oil Tools | 200 | 35% efficiency |

| Overall Yield | 95% | High |

Cases demonstrate AM’s versatility, with savings varying by industry—vehicles prioritize weight, machinery durability.

How to Work with Contract Manufacturers for Flexible Capacity and Scaling

Partnering with CMs like MET3DP provides scalable capacity: Start with prototypes, ramp to series via shared IP vaults. Tips: Define SLAs for 99% on-time, use portals for tracking.

Case: USA OEM scaled from 10 to 500 units seamlessly, avoiding capex. 2026: Cloud AM networks enable global-yet-local scaling.

Benefits: Access expertise, reduce overhead 40%. Select via audits, NDAs.

Insights: Collaborative design reviews cut errors 20%.

FAQ

What is the best pricing range for metal 3D printing low-volume production?

Please contact us for the latest factory-direct pricing at MET3DP.

How does metal AM compare to CNC for small batches in the USA?

AM excels in complexity and low MOQ, with 2-4 week leads vs. CNC’s 1-2, but CNC offers better finishes for simple parts.

What materials are best for low-volume metal 3D printing?

Titanium for aerospace, stainless for general, Inconel for high-temp—chosen based on application strength needs.

Can metal 3D printing scale beyond low-volume in 2026?

Yes, with multi-machine farms, it supports up to mid-volume (1,000+ units) economically.

What are common challenges in AM for USA manufacturers?

Post-processing and certification; mitigated by certified partners like MET3DP.